1″ Amasokhethi Anomthelela

imingcele yomkhiqizo

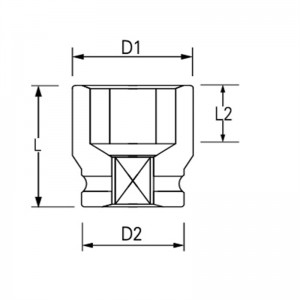

| Ikhodi | Usayizi | L | D1±0.2 | D2±0.2 |

| I-S157-17 | 17mm | 60mm | 34 | 50 |

| I-S157-18 | 18mm | 60mm | 35 | 50 |

| I-S157-19 | 19 mm | 60mm | 36 | 50 |

| I-S157-20 | 20mm | 60mm | 37 | 50 |

| I-S157-21 | 21 mm | 60mm | 38 | 50 |

| I-S157-22 | 22 mm | 60mm | 39 | 50 |

| I-S157-23 | 23 mm | 60mm | 40 | 50 |

| I-S157-24 | 24mm | 60mm | 40 | 50 |

| I-S157-25 | 25mm | 60mm | 41 | 50 |

| I-S157-26 | 26 mm | 60mm | 42.5 | 50 |

| I-S157-27 | 27 mm | 60mm | 44 | 50 |

| I-S157-28 | 28mm | 60mm | 46 | 50 |

| I-S157-29 | 29 mm | 60mm | 48 | 50 |

| I-S157-30 | 30mm | 60mm | 50 | 54 |

| I-S157-31 | 31 mm | 65 mm | 51 | 54 |

| I-S157-32 | 32 mm | 65 mm | 52 | 54 |

| I-S157-33 | 33 mm | 65 mm | 53 | 54 |

| I-S157-34 | 34 mm | 65 mm | 54 | 54 |

| I-S157-35 | 35 mm | 65 mm | 55 | 54 |

| I-S157-36 | 36 mm | 65 mm | 57 | 54 |

| I-S157-37 | 37 mm | 65 mm | 58 | 54 |

| I-S157-38 | 38mm | 70mm | 59 | 54 |

| I-S157-41 | 41 mm | 70mm | 61 | 56 |

| I-S157-42 | 42 mm | 70mm | 63 | 56 |

| I-S157-46 | 46 mm | 70mm | 68 | 56 |

| I-S157-48 | 48mm | 70mm | 70 | 56 |

| I-S157-50 | 50mm | 80mm | 72 | 56 |

| I-S157-55 | 55 mm | 80mm | 78 | 56 |

| I-S157-60 | 60mm | 80mm | 84 | 56 |

ethula

Amasokhethi omthelela ayithuluzi elibalulekile lanoma yimuphi umakhenikha. Kungakhathaliseki ukuthi ungumakhenikha ochwepheshe noma i-DIYer yangempelasonto, ukuba nesethi yamasokhethi ekhwalithi ephezulu kungenza umsebenzi wakho ube lula futhi usebenze kahle. Uma kukhulunywa ngamasokhethi womthelela, kunezici ezimbalwa ezibalulekile okufanele uzicabangele: umthamo we-torque ephezulu, ukwakhiwa okuhlala isikhathi eside, nosayizi abahlukahlukene.

Isici esibalulekile okufanele sicatshangelwe lapho kukhethwa isokhethi yomthelela into eyenziwe ngayo. I-CrMo steel iyinsimbi eyaziwa ngamandla ayo kanye nokuqina, okuyenza ibe ukukhetha okuhle kakhulu kwezisekelo zomthelela. Ukwakhiwa komgunyathi kwalezi zisekelo kuthuthukisa ngokwengeziwe amandla azo futhi kuqinisekisa ukuthi zingakwazi ukumelana namazinga aphezulu e-torque ngaphandle kokuqhekeka noma ukuphuka.

Esinye isici esibalulekile okufanele sicatshangelwe inani lamaphuzu kusokhethi. Amasokhethi omthelela ngokuvamile afika ngomklamo wamaphoyinti angu-6 noma angu-12. Idizayini enamaphuzu angu-6 ikhethwa omakhenikha abaningi ngoba inikeza ukubamba okuqinile kwezinsimbi, inciphisa ingozi yokushelela nokuzungeza.

Mayelana nobubanzi besayizi, isethi enhle yamasokhethi womthelela kufanele ihlanganise osayizi abahlukahlukene ukuze kufakwe izixhumi ezihlukene. Kusukela ku-17mm kuya ku-60mm, isethi ephelele yamasokhethi iqinisekisa ukuthi unosayizi ofanele wanoma yimuphi umsebenzi ohlangana nawo.

imininingwane

Izisekelo zomthelela wezinga lezimboni zihlolwa ngokuqinile ukuze kuqinisekiswe ukuqina nokuthembeka. Lezi zisekelo zakhiwe ukuze zimelane nokusetshenziswa njalo ezindaweni ezinokhahlo ngaphandle kokuguga. Zenzelwe ukuletha ukusebenza okungaguquki ngisho nasezimeni ezinzima kakhulu, okuzenza zibe ukukhetha okuthenjiwe kochwepheshe.

Ukucatshangelwa okubalulekile uma kukhulunywa ngamasokhethi womthelela ukumelana nokugqwala kwawo. Into yokugcina oyifunayo indawo egqwalile futhi okunzima ukuyisebenzisa. Bheka amasokhethi womthelela aklanyelwe ngqo ukumelana nokugqwala, uqinisekisa ukuthi azohlala iminyaka.

Okokugcina, kufanelekile ukusho ukuthi ukusekelwa kwe-OEM kubalulekile ekuletheni ikhwalithi ephezulu, amasokhethi womthelela ahambisanayo. Ngosekelo lwe-OEM, ungaqiniseka ukuthi uthola umkhiqizo oyiqiniso, onokwethenjelwa osekelwa umenzi wokuqala.

Ekuphetheni

Sengiphetha, amasokhethi womthelela adlala indima ebalulekile kunoma iyiphi ibhokisi lamathuluzi lanoma yimuphi umakhenikha. Isici ezicini ezinjengomthamo we-torque ephezulu, impahla yensimbi ye-CrMo, ukwakhiwa komgunyathi, idizayini enamaphuzu angu-6, ububanzi bosayizi, ikhwalithi yezinga lezimboni, ukumelana nokugqwala nokusekelwa kwe-OEM ukuze kuqinisekiswe ukuthi utshala esokhethini esinomthelela esizohlangabezana nezidingo zakho. Kudingeka futhi imelane nokuhlolwa kwesikhathi. Ngakho-ke, kungakhathaliseki ukuthi uchwepheshe noma u-DIYer, qiniseka ukuthi ukhetha isokhethi elinomthelela eliqinile futhi eliletha ukusebenza okudingayo.